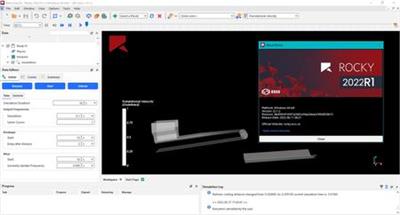

ESSS Rocky DEM 2022 R1.2 (22.1.2) (x64)

ESSS Rocky DEM 2022 R1.2 (22.1.2) | 1.9 Gb

Product:ESSS Rocky DEM

Version:2022 R1.2 (22.1.2)

Supported Architectures:x64

Website Home Page :Original_Link_https://rocky.esss.co/

Languages Supported:english

System Requirements:Windows or Linux *

Size:1.9 Gb

ESSS announces the release of its top-tier particle dynamics modeling software Rocky 2022R1. This release enables faster, easier, and accurate particle dynamics simulations with larger numbers of particles while offering tighter integration with other physics.

Engineers will have access to a science-based, easy-to-use material calibration platform, plus the ability to accelerate simulation as much as 10x by using a Multi-zone Dynamic Domain. Particle-laden free surface flows can be simulated using a new multi-CPU and a multi-GPU SPH-DEM coupled solver.

The 2022R1 Material Wizard dovetails into Rocky’s calibration suite and is designed to jump-start Rocky simulations by turning real-world material information into ready-to-use setup parameters. The Wizard compares experimental data with a built-in material database and uses AI/ML techniques to provide the best required material-related simulation parameters. The Wizard is fully customizable and configurable to individual applications or groups of materials and can be downloaded directly from Rocky’s customer portal.

The Multi-zone Dynamic Domain enables faster simulation, making it possible to simulate applications with several millions of particles by both reducing memory requirements and speeding computational time. This simulation optimization methodology enables dynamic calculation zones of interest to include or minimize contact detection inside or outside of the zones, based on where the particles are active. For example, the simulation of disk harrow equipment (shown below) was accelerated by 9x using the new dynamic simulation domain capability.

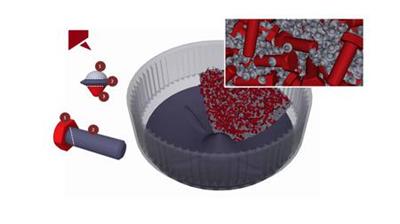

In response to a growing demand to model complex particle shapes in applications beyond traditional DEM, especially in manufacturing, the current Rocky release enables assembling of different particles to form new shapes. The Particle Assembly model improves computational performance for complex concave shape particles and enables simulation of limitless discrete particle shapes.

Polishing/Finishing Process: Simulation of bolt finishing equipment using the Particle Assembly model runs 36x faster with 22x less memory.

Another relevant capability in the 2022R1 release is the introduction of a bond model that extends Rocky’s advantage in modeling particle breakage. This new model simulates the behavior of material represented as a collection of bonded particles of any shape. In cases where the material can be characterized, the model predicts the material response to an applied dynamic force.

Rocky is launching the beta version of its native SPH-DEM solver kernel with a focus on particle-laden free surface flows. The solver is developed native to multi-GPUs and multi-CPUs. The SPH-DEM coupling offers an effective simulation approach for slurry flows, for example. The solution methodology efficiently accounts for the presence of different sized and shaped particles as well as fluid-particle interaction.

The 2022R1 release extends Rocky’s applications of Ansys CFD coupling that involve particle size changes due to mass and heat transfer (conduction, convection, and radiation) with or without chemical reactions. The effect of particle size changes can be used in particle drying, particle gasification, and pyrolysis. For transient calculations, CFD and DEM are coupled in multiple ways, including the new 1-Way transient developed to accelerate simulation with moving geometries, such as pumps and stirred tanks.

The 2022R1 is a robust release and includes a host of new and improved capabilities. Rocky is a new platform for modeling discrete solid mechanics beyond traditional DEM applications.

ROCKY DEMallows precise prediction of the particle behavior of granular and liquid systems by analyzing media flows, energy absorption rates and particle breakage. Wherever large quantities of particles and bodies are set into motion in bulk, mixing, slipping or flow processes regardless of their size, shape, material or adhesion, ROCKY can help to understand and improve the processes.

These are, on the one hand, measures for optimizing the movement of the mass, for example to minimize material losses or to prevent or suppress dust formation. On the other hand, the results provide important information for efficiently designing peripheral products, for example to increase the service life of conveyor belts and other components.

ROCKY DEM optimizes, among other things, agitator mills, SAG mills, crushers and high-pressure grinding rollers, the particle spectrum ranges from small synthetic parts such as tablets to gravel.

With ROCKY for ANSYS particle simulation can be extended with important structural and flow-mechanical information. These are achieved by a complete integration in ANSYS Workbench. The compact and user-friendly user interface of ROCKY for ANSYS ensures uncomplicated installation and operation. CAD geometries can also be imported easily and quickly.

Extend your multiphysics simulations with Rocky DEM and Ansys integration

Rocky DEM and Ansys integration lets you analyze complex problems from a new perspective: particle dynamics coupled with the Ansys multiphysics simulation solution.

Engineering Simulation and Scientific Software(ESSS)is an innovative international provider of engineering simulation products and services operating in more than 10 countries. With over twenty-five years of experience and over 200 employees, ESSS is a well-established Ansys channel partner. In addition, ESSS develops new simulation tools, runs the ESSS institute, and drives broader adoption of customized CAE solutions in the energy industry.